lightweight solutions

Innovative Lightweight Small Arms Ammunition

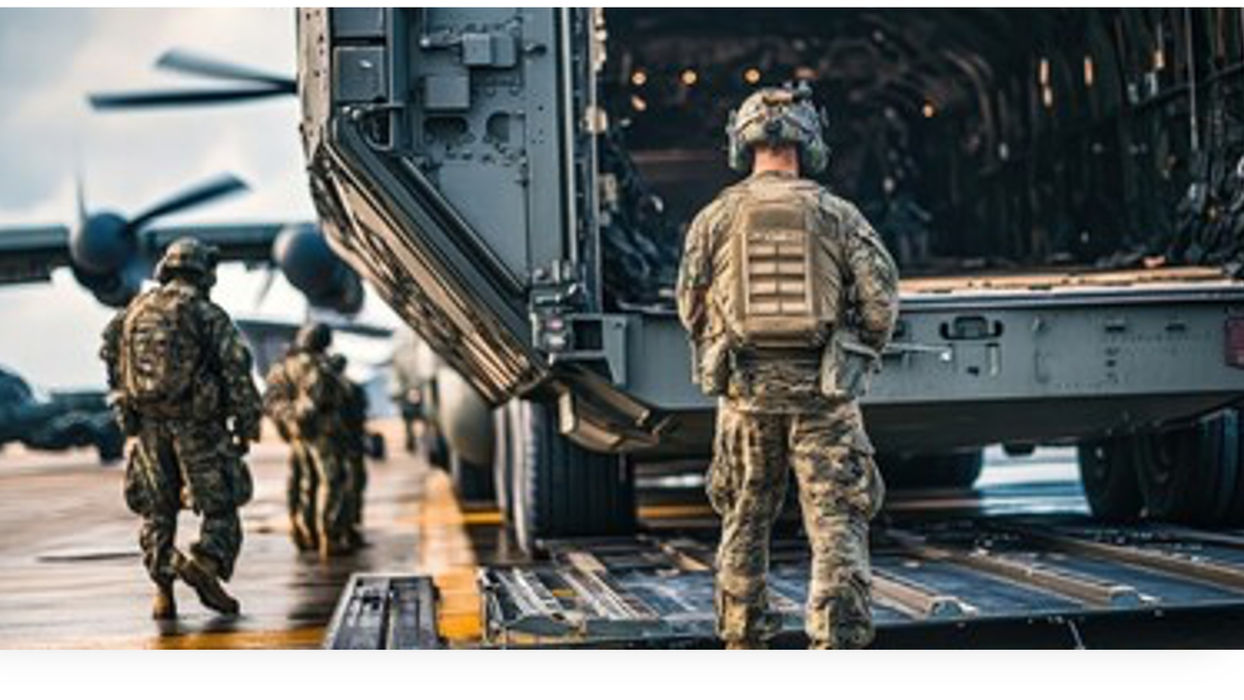

Supporting The U.S. Army’s Top Priority Of Increasing Lethality, Enhancing Mobility, And Improving The Survivability Of Soldiers

LIGHTEN UP FOR SOLDIERS

Reducing the heavy load that soldiers carry, which includes weapons, ammunition, sustainment gear, protection, and mission command equipment, remains a top priority for the Army. The Product Manager for Small Caliber Ammunition (PdMSCA), a component of the Project Manager for Maneuver Ammunition Systems (PM MAS) within the Joint Program Executive Office for Armaments and Ammunition (JPEO A&A), is dedicated to advancing this goal through the development and deployment of lightweight small-caliber ammunition.

Efforts are underway to test prototypes and explore alternative materials like polymer and steel to replace traditional components of ammunition cartridges, reducing their weight without sacrificing effectiveness.

An infantry soldier’s weight, consisting of their combat load and mission-critical gear, has significantly increased over time. During the Gulf War, soldiers carried about 89 pounds, but by Operation Enduring Freedom and Operation Iraqi Freedom, this number had risen to 133 pounds and currently stands at around 122 pounds. PdMSCA is focused on refining 7.62 mm ammunition with lighter metallic and polymer casings, offering weight reductions of roughly 13-15% and 20-24%, respectively. This translates into a savings of approximately 13 pounds with metallic casings and 17 pounds with polymer casings for an M240 machine gun crew. Beyond the tactical advantages for individual soldiers, switching to lightweight small-caliber ammunition could also lead to significant reductions in transportation costs and improve the overall throughput of ammunition within the Army's logistical systems. Replacing traditional brass casings with polymer would reduce the weight of a pallet of 7.62 mm ammunition by more than 400 pounds, allowing for additional pallets to be loaded and transported on military cargo ships and aircraft.

Lightening the weight soldiers carry into the battlefield has been one of the top priorities for the US Army. PM MAS has been working for years to reduce the weight of 7.62mm ammunition. Until very recent progress demonstrated by FPPD, there has been no solution for polymer cased 7.62mm ammunitions to meet the demanding performance requirements for surviving all desired operational temperatures, particularly at the extreme low temperature of -65°F.

FPP DEFENSE'S SOLUTIONS

FPPD brings over 25 years of extensive experience collaborating with various Department of Defense (DOD) stakeholders to develop innovative small arms ammunition. FPPD has successfully completed numerous development contracts, including:

Lightweight Polymer Cased 5.56mm Ammunition for US Army

Lightweight Polymer Cased .338 cal Ammunition for SOCOM

Lightweight Combustible Small Arms Ammunition for US Army

Novel Long-Range Sniper Sabot 7.62mm, .338 and .50 cal Ammunitions for SOCOM

Lightweight Polymer Cased Small Arms Ammunition for US Navy

Lightweight 7.62mm Polymer Cased Ammunition for US Army

With expertise in lightweight material development and optimization for very demanding ballistic applications, FPPD Defense has expanded its technical capabilities to include modeling and simulation of ballistic cycles for different weapon systems, component and system design, injection mold design and mold flow simulations, mold construction, component injection molding, prototype case fabrication, cartridge prototype loading and assembling, and small volume cartridge production. In addition, FPPD specializes in Electronic Pressure Velocity and Action Time testing (EPVAT), and F&C ballistic testing.

Leveraging its extensive in-house research, prototyping, and manufacturing capabilities, FPPD has developed and successfully demonstrated innovative lightweight small arms ammunition technology. This technology meets the rigorous demands of lightweight ammunition, ensuring reliable performance across a wide range of operational temperatures—from 125°F to as low as -65°F—on all weapons, including rifles and machine guns, even under the demanding conditions of the M240B machine gun.

FPPD is collaborating with DEVCOM-Armaments Center and PM-MAS to demonstrate its lightweight polymer-cased 7.62mm ammunition. Additionally, FPPD is establishing a pilot production facility in Fredon, New Jersey, to support prototype cartridge development and small-volume production, including the loading and assembly of 7.62mm lightweight polymer cased cartridges and other small arms ammunition.

LIGHTWEIGHT 7.62MM AMMUNITION DEMONSTRATION

Our soldiers carry up to 120 lbs of load going into the battlefield. Therefore, the Army, Navy, and Marine Corp have an urgent need to lighten the soldiers weight to improve their mobility, enhance survivability, and increase lethality. A major portion of the weight they bear comes from the ammunition they carry into the battlefield. Reducing that weight through the development of of lightweight ammunition is a top priority for our warfighters.

As a result of FPPD’s innovative polymer case ammunition design, state of the art modeling and simulation, superior polymer case assembly process, and rigorous ballistic performance optimization, FPPD has successfully developed and demonstrated its 7.62mm Ball lightweight polymer cased ammunition that satisfy EPVAT requirements and more critically, the F&C requirements for M110 and M14 rifles, and MK48 and M240B machine guns.

Working with Navy’s NAVSEA Picatinny Detachment, Army’s DEVCOM-Armaments Center and PM-MAS, FPPD has successfully demonstrated lightweight ammunition technology. Based on the Army's testing results at a government facility, FPPD's lightweight 7.62mm polymer cased ammunition is the only lightweight ammunition that can survive all operation temperatures in the range of -65F to 160F on the MK48, M240, and M240B machine guns.

VIEW DEMOS

FPP DEFENSE’S EXTENSIVE EXPERIENCE AND DEVELOPMENT EFFORTS ON LIGHTWEIGHT 7.62MM AMMUNITION

Over the past 25 years, FPPD has collaborated with DOD stakeholders on developing and fielding the lightweight 7.62mm polymer cased ammunition to reduce weight for soldiers and has invested significant effort in developing a novel high strength and super-ductile polymer material, an innovative lightweight polymer case design, and a novel fabrication process to overcome technical challenges.