NOVEL TECHNICAL capabilities

Lightweight Material Development

25 Years Of Success In Developing And Commercializing Innovative Lightweight Plastic Materials, High-performance Composites, And Advanced Nanocomposites For Demanding Applications

LIGHTWEIGHT PLASTIC MATERIALS

Metals have densities ranging from 2.7g/cm3 for aluminum to 8.0 g/cm3 for stainless steel, while most plastics have densities around 0.9 to 1.5 g/cm3. There is no doubt replacing metal materials with plastics can significantly reduce products weight. Moreover, it is known that some high-performance plastic materials or composites even have higher specific strength than steel.

When FPPD started interacting with the Army’s engineers 25 years ago, there was a common belief that plastics are limited in application potential and cannot replace heavy metals. After carefully analyzing their experiences of using plastic materials in their efforts to reduce weight, it became obvious that some of the Army engineers underestimated the challenges of selecting the right material for their applications.

They typically just gave the project to a molder who built a mold based on the past drawing and selected a commercial plastic product, then molded the parts for the Army engineer’s evaluation. More often than not, this approach did not lead to a positive result.

Plastics are normally divided into high-performance, engineering, and commodity grades, with the high-performance plastics being up to 10 times stronger than commodity plastics. Almost all thermoplastic resins can be modified through blending with different polymers. Additives, fillers, processing aids, and physical or chemical treatments can be used to blend materials that may not be naturally compatible or miscible to obtain specific performance requirements. This blending process often results in a material with superior performance properties compared to either individual polymer resin, and can meet the stringent requirements for military equipment.

For example, a fully loaded ammunition container needs to survive a 7-foot drop in the temperature range of -65°F to 125°F. These requirements pose significant challenges for plastic materials, and therefore, extensive knowledge of polymer processing is required to develop a material durable enough to survive those conditions.

FPPD has over 25 years of successful experience in developing and commercializing a wide range of thermoplastic resins, from commodity polyolefins to engineering and high-performance plastics, for automotive, consumer, and defense applications. Our Parsippany facility features a pilot resin compounding line for resin formulation development, as well as three injection molding machines to produce prototypes and meet the needs of lightweight material development

HIGH-PERFORMANCE COMPOSITES

Glass fiber or carbon fiber composites are commonly used for demanding applications that require high strength and/or high rigidity. Depending on the application, there are two types of plastic composites: thermoplastic and thermoset composites.

Thermoplastic composites usually have short or long fibers and are typically designed to be injection molded into the final parts. On the other hand, thermoset composites are designed to achieve high strength and/or modulus for demanding structural applications. Thermoset composites are typically continuous carbon or glass fiber composites in uni-directional or bi-directional fabric constructions and are typically processed via compression molding, filament winding, or web lay-up technique.

FPPD has extensive experience in developing a variety of thermoplastic composites. We are equipped with both a pilot-scale compounding line and a production-scale compounding line. These lines enable us to produce glass or carbon fiber-filled engineering plastics with fiber content up to 70%. Our focus is on providing cost-effective material solutions for heavy metal replacement applications, helping to reduce weight. FPPD also has expertise in resin formulation and processing. We develop thermoplastic composite materials to meet specific requirements, such as exceptional flowability for complex part geometries. Additionally, our materials offer better dimensional stability for applications with tight tolerances and improved impact resistance.

FPPD has also accumulated extensive experience in epoxy, polyester, and high-temperature resistant polyimide composite fabrication using either unidirectional pre-pregs or bidirectional fabric pre-pregs. FPPD has two compression molding machines and one vacuum compression molding machine to fabricate and produce the thermoset composite prototypes for evaluation and testing.

FPPD’s novel capability in high-performance composite materials will allow it to support DOD stakeholders in developing lightweight material solutions to meet the demanding military requirements.

ADVANCED NANO-COMPOSITES

Nano-composite materials have a high potential to attain outstanding mechanical and physical performance in thermoplastic resin applications. However, for the past 20 years, the commercialization of nanocomposite materials has stagnated. Most nanocomposite products on the market today only deliver marginally improved mechanical performance.

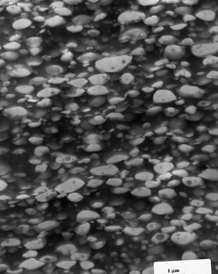

One of the major hurdles for the commercialization of nano-composite materials is the lack of expertise in effectively dispersing the nanocomposite into the plastic resins. Most nanocomposite fillers, such as carbon nanotubes, graphene, or Nanoclay, tend to form agglomerates or tightly bonded layer structures and are very difficult to disperse to form the desired fully exfoliate nano-composite layers in the plastic resins.

FPPD has extensive experience in dispersing nanocomposites into various thermoplastic resins to achieve a complete exfoliation of each nanocomposite layer into the plastic resins by using processing means, chemical modifications, and dispersion aids. FPPD has discovered that fully exfoliated nanocomposites have superior mechanical and physical properties compared to poorly dispersed nanocomposites. For example, the typical commercially available 4% multi-wall carbon nanotube composite has low ductility (i.e., low elongation-to-break. However, a fully exfoliated CNT composite not only has much higher mechanical strength but also very high elongation-to-break. This means that well-dispersed nanocomposites can not only improve the mechanical strength and stiffness but also retain or improve ductility.

FPPD’s novel technical capability in developing advanced nano-composite materials can deliver innovative high-performance lightweight material solutions to its military collaborators to reduce weight without sacrificing performance.

LIGHTWEIGHT MATERIAL DEVELOPMENT & PRODUCTION CAPACITY

FPPD's in-house equipment, which includes a small-scale twin screw compounding line and a small-scale injection molding machine, enables rapid turnaround times for developing new lightweight materials to meet DOD customers’ new lightweight material development requirements.

For instance, formulations can be compounded with the twin screw extruder and then pelletized; these pellets are subsequently injection molded into specimen molds. Various tests are conducted on the specimens to verify that their properties meet the required standards. This process ensures a turnaround time of just one to a few days per formulation, significantly shortening the project timeline. Additionally, the high-temperature configuration of the extruder allows for the processing of ultra-high-temperature engineering materials, withstanding temperatures up to 850°F.

When customers have production needs, FPPD boasts extensive experience in scaling from lab-scale to full-scale production. Their production-scale equipment allows in-house production at rates of up to 2,000 lbs/hr.

Similar to the lab compounding line, the production line is equipped with an ultra-high temperature configuration, capable of operating at temperatures as high as 850°F. Thanks to a unique design, FPPD’s production line can function as both a sheet co-extrusion line and a pelletizing compounding line, enabling FPPD to provide both sheet extrusion and compounding production services to DOD customers.