lightweight solutions

Innovative High-Performance Transparent Armors

Supporting The U.S. Army's Priority Of Enhancing Protection To Improve The Survivability Of Our Warfighters.

OUR SOLDIERS NEED BETTER PROTECTION

A study of ocular war injuries among Iraqi insurgents during the first nine months of 2004 revealed that improvised explosive devices (IEDs) were responsible for 51% of injuries, making them the leading cause. Gunshot wounds (GSW) and mortars each accounted for 10% of these injuries.

Munitions fragments were the most common cause of ocular injuries, accounting for more than 82% of all ocular adnexal injuries. While current polycarbonate ballistic eyewear may have prevented some of these injuries, a more effective transparent armor material is needed to provide improved eye protection for soldiers.

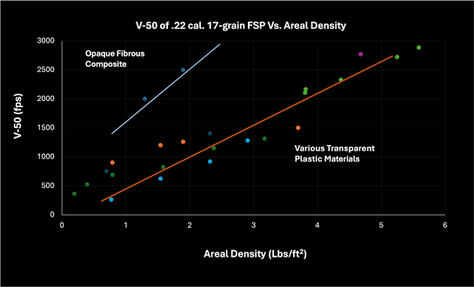

Conventional transparent armor materials used for soldier facial protection are made of either polycarbonate or polycarbonate/polymethylmethacrylate hybrids. Although they provide satisfactory protection, their ballistic performance is vastly inferior to fiber-reinforced composite materials. Unfortunately, fiber-reinforced composite materials cannot be used for facial shielding due to their opaque nature. Therefore, Project Manager – Soldier Protective Equipment (PdM-SPE) of PEO Soldier and DEVCOM-Soldier Center is actively searching for a better transparent armor material to significantly improve facial protection for our soldiers.

In recent years, the U.S. Army has extensively evaluated and researched various polymer materials as candidates for transparent armor, aiming to replace polycarbonate. Among the materials tested are amorphous nylon, polyurea, and polyurethane, which only provide marginal improvement in ballistic performance. The ballistic performance gap between transparent armor and opaque fiber composites remains significant, highlighting the urgent need for high-performance transparent armor technology that approaches the ballistic capabilities of fiber composites to better protect soldiers.

FPP DEFENSE'S SOLUTIONS

FPPD has more than 25 years of extensive experience working with various DOD stakeholders in developing novel lightweight transparent and composite armors, including

Innovative Lightweight Transparent Armor – DEVCOM-Soldier Center

Innovative Lightweight EOD Face Shields – from DEVCOM-Soldier Center

Innovative Ballistic resistant Spectacle – DEVCOM-Soldier Center

Advanced Lightweight Composite Armor For M-ATV – DEVCOM-Ground Vehicle Systems Center

Lightweight Low-Cost Vehicle Transparent Armor For M-ATV – DEVCOM-Ground Vehicle Systems Center

Innovative Lightweight High Temperature Composite Armor For EFV –Marine Corp.

Manufacturing Of Lightweight Transparent Armors – ManTech and DEVCOM-Army Research Laboratory

Supported by DEVCOM-Soldier Center since 2005, FPPD has overcome many technical obstacles and challenges, successfully turning an unproven material concept into a novel super-high-strength polymer material technology. FPPD specializes in lightweight material development for improved ballistic energy absorption, innovative polymer material processing for high-performance material manufacturing, and prototype fabrication and testing of spectacles, goggles, and face shields. In addition, FPPD excels in ballistic testing with fragment simulating projectiles (FSP), armor piercing simulating projectiles (APSP), and small arms ammunitions, and the development of novel hard coatings and anti-fog coatings. With this expertise, FPPD successfully fine-tuned the production process and demonstrated that novel transparent armors can have good optical properties, excellent multi-shot performance, and a very high ballistic performance-to-weight ratio and improved protection from fragment impact.

With support from the US Army, FPPD has established a full-scale production line in Parsippany, New Jersey, to produce the novel super-high-strength polymer materials. FPPD is also in the process of establishing a secondary pilot production facility in Fredon, New Jersey, to perform small volume production of transparent armor prototypes and to conduct ballistic testing for the armor using a high-performance air gun.

With the new production line nearly operational, coming online, and additional development efforts, FPPD is expecting to further improve the ballistic performance of the super-high-strength polymer material technology, bringing it closer to the ballistic performance of UHMWPE armors for future generations of the transparent armors.

SUPERIOR PERFORMANCE AT LOWER COST

The Army is on the lookout for lightweight solutions that provide excellent protection for soldiers in combat fields, including transparent armor. Currently available commercial transparent materials, such as PC, PMMA, and TPU materials, are not particularly lightweight and low in ballistic resistance, especially for facial protection.

FPPD has collaborated with several stakeholders in the Army since 2005 and successfully developed and demonstrated the innovative Super High Strength Polymer Material (SHSPM) technology to significantly narrow the ballistic performance gap between conventional plastic materials for transparent armors and fibrous composite materials for opaque armors.

An essential part of transparent armor is the ability to see through it without vision impairment. FPPD’s SHSPM materials have great optical properties compared to current transparent armor materials, with much higher transmittance, which greatly enhances vision at night without the need to remove the spectacle or goggle. Despite significant improvements in weight savings and ballistics, FPPD’s SHSPM does not compromise on optical properties, and the haze values of SHSPM goggles and spectacle lenses easily surpass military specification MIL-PRF-32432.

Once FPPD’s new production line becomes operational, the ballistic performance of the future generations of these novel high-performance materials can further reduce the ballistic performance gap to the UHMWPE fiber composite materials, but at a much lower cost (as low as 10-20% of Dyneema or Spectra composite materials). The lower cost nature of these higher-performance armor materials will allow the U.S. Army to provide more extensive and highly effective protection to our soldiers.

Advancements of this high-performance, lightweight transparent armor material will allow FPPD to support the U.S. Army’s priority of providing better protection to improve the survivability of U.S. Soldiers.

FPPD’s LIGHTWEIGHT HIGH-PERFORMANCE TRANSPARENT ARMOR

FPPD has successfully developed an innovative high-performance transparent armor material technology from initial concept to proven technology and has built a full-scale production line with the capacity to produce SHSPMs. This allows FPPD to deliver the transparent armors with ballistic performance close to that of opaque fibrous composite armors. With this advanced transparent armor material technology, FPPD is working towards fulfilling the Army’s need to improve the survivability for U.S. soldiers.

40%

Weight Saving Achieved For FPPD’s MPFS Face Shields

250%

Greater Absorption of Ballistic Energy from FPPD’s Spectacle Lens At The Same Areal Density

90%

Cost Saving Delivery of FPPD’s SHSPM Material Over Fibrous Composite Materials

NOVEL FULLY TRANSPARENT BALLISTIC SHIELDS

Ballistic shields are used by civilian law enforcement, especially tactical entry or special weapons and tactics teams. Shields are used for the protection of officers and especially in situations where officers have no natural cover and shields approach armed suspects.

A key aspect of these shields is that they can be held in one hand so that the officer can accurately use and reload a handgun or other small arms. A key aspect in this is that the shield must be both light enough to hold in one hand and provide ballistic protection. Traditionally, they are composed of fiber composite material with a small window to allow the holder to see through. Use of this small window reduces the user’s field of view and situational awareness significantly, a serious downside to current ballistic shields.

The fully transparent shields in the market today do not have ballistic resistance, even for a handgun bullet. FPPD is working to develop a fully transparent ballistic shield for the civilian law enforcement market. With the current iterations of ballistic shields, the user’s vision is restricted to the small viewing port on the front of the shield. With a fully transparent shield, the user will have a larger field of view and the ability to see around them. Having a fully transparent shield would greatly increase the effectiveness of any personnel using it. SHSPM weight-saving properties are a perfect complement to the ballistic shields need to be lightweight, affording the user a lighter load and the ability to move the shield into position faster. With the advancement of the ballistic performance of FPPD’s SHSPM technology approaching that of the fiber composite materials, the fully transparent ballistic shield will provide the users not only the ballistic protection but also better situation awareness.