NOVEL TECHNICAL capabilities

Design, Modeling + Simulation

Extensive Experience In Designing Novel Munitions, Packaging, Facial Protection Systems, And Utilizing Proprietary Modeling And Simulation Tools To Validate Design Concepts Before Prototyping

DESIGNING MUNITIONS AND PACKAGING SYSTEMS

The U.S. military demands advanced design, unparalleled reliability, durability, and mission-readiness. These requirements present significant challenges for plastic components, which are often utilized to reduce weight yet must still meet stringent military specifications and performance requirements for a wide operational temperature range.

With more than twenty years of expertise in advanced 3D modeling and product visualization, FPPD delivered numerous technically sophisticated designs that meet the rigorous demands of defense applications, including:

Composite container packaging systems

PA92, PA103, PA120, and PA 161 containers with Insensitive Munition (IM) capability

Improved safety handheld signal packaging system

Rocket and MK48 warhead with IM capability

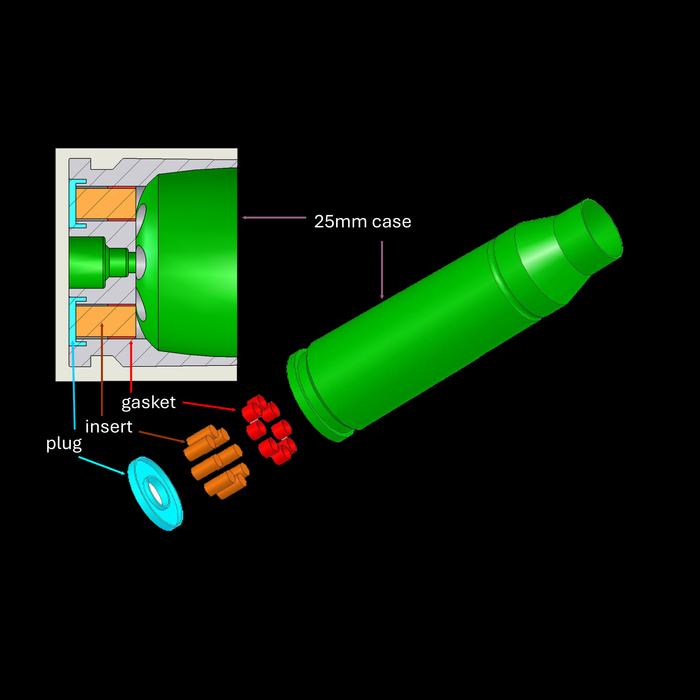

25mm and 40mm cartridges with IM capability

5.56mm, 7.62mm, .338 cal and .50 cal polymer cased ammunitions

5.62mm and 7.62mm combustible ammunitions

7.62mm, .338 cal and .50 cal saboted ammunitions

High ballistic resistant spectacles, goggles, and face shields

Innovative Armored Vehicle-Launched Bridge (AVLB) linkage assembly

Moreover, FPPD has gained extensive experience in injection mold design, enabling the development and adaptation of optimized tooling to ensure the final prototypes meet design requirements and eliminate potential weaknesses from improper mold design in injection-molded parts or systems.

FPPD collaborates closely with DOD stockholders from the initial concepts to final products, ensuring that each design delivers the intended solution and adheres to military specifications and stringent performance requests. Further, FPPD utilizes modeling and simulation capabilities to optimize and fine-tune the designs for manufacturability, cost-effectiveness, performance, and long-term operational needs.

UTILIZING MODELING & SIMULATION TO VALIDATE DESIGNS

Modeling and simulation tools are critical to any design effort by providing valuable and cost-effective models that predict a part’s performance, optimize design features, and validate design concepts before building the prototypes.

FPPD leverages the latest simulation tools to thoroughly analyze and validate designs before physical prototyping. Using non-linear finite element analysis (FEA), FPPD can evaluate crash and impact scenarios, analyze multi-physics interactions, and assess system safety factors. By integrating simulations into the design process, it is possible to minimize the need for extensive physical testing, accelerate development cycles, and ensure products are fully optimized to withstand real-world challenges.

For example, FPPD has successfully employed modeling and simulation tools to predict potential damages on the MK12 Poly Plug from the hoist and ram process in the 5” gun. In addition, it helped FPPD to select the right resin system for manufacturing the plugs. Another example is using modeling and simulation methods to predict the maximum impact force and potential damage to the end cap of the 155mm composite container during a 45O drop from a seven-foot height, allowing for design adjustments before producing protypes for testing.

FPPD conducted extensive modeling and simulation in the development of lightweight polymer cased 5.56mm, 7.62mm and .50 cal ammunitions. Through the use of these tools, an innovative lightweight polymer cased ammunition was designed to meet intense performance requirements. Utilizing this novel technical capability, FPPD has recently demonstrated its lightweight polymer cased 7.62mm ammunition can survive the ballistic cycles on various rifles and machine guns at all operational environments, including the extreme low temperature of -65F.

With advanced modeling and simulation capabilities, FPPD can help the DOD stakeholders to gain a strategic edge by improving operational efficiency, reducing risks, and ensuring systems are fully optimized to shorten the development cycle.